Intro : repairing back wheel Dualtron Victor

Hi everyone and welcome to our new MoovMoov tutorial!

In this tutorial we’re going to look at how to change the tyre and inner tube on the rear wheel of an electric Dualtron Victor scooter. We tried to make sure that this video is as complete as possible so that you have all the information you need to succeed!

Remove the mud guard

So let’s begin by unscrewing the mud guard. It is fixed with 4 screws. 2 on the left part of the back fork. And 2 on the other side.

🛒 Inner Tubes for Dualtron Victor (10×2.50, 90/90 angled valve)

🛒 Tire for Dualtron Victor (80/65-6 Road)

🛒 The perfect valve extension for easily inflating your Dualtron tires

Removing the mudguard

Let’s start by unscrewing the mudguard.

It is fixed with 4 screws.

2 on the left side of the rear fork.

And 2 on the other side.

To remove it, simply remove the two screws on the left side.

Then we can unscrew the two nuts on the right and remove everything.

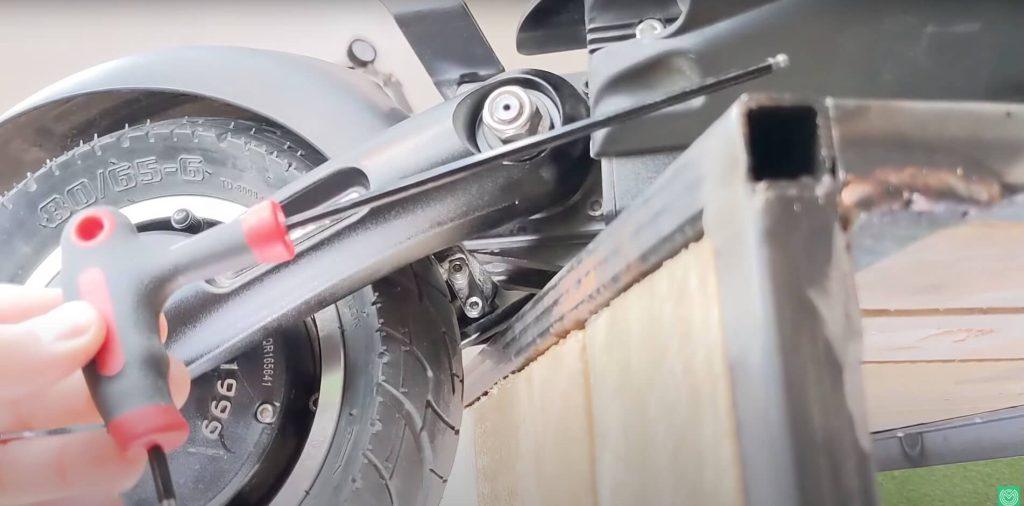

So here we unscrew the two mudguard screws with a long 4mm Allen key.

To access these screws more easily, here’s the little technique we like to use:

We pass a ratchet strap around the tire.

Make sure there is no air left in the tire.

And tighten the wheel.

This allows us to reduce the circumference of the tire and have more space to unscrew the mudguard screws.

Now we can remove the strap.

Unscrew the two nuts with an 18mm wrench.

And remove the two washers.

Removing the rear fork arm

Now, we can finally remove the right arm of the rear fork.

For that, we have two techniques.

Technique 1: We place a cloth inside the arm to protect it.

We place a long Allen key.

And we hit it with a hammer to remove the arm from its axis.

Technique number 2: We can use a small puller.

Simply place it on the fork axles and pull the arm outward.

Separating the rear wheel from the motor

Now, we can remove the 6 screws from the rim.

If it’s the first time you unscrew them, there may be thread locker on these screws and they may be tight.

So, to avoid damaging a screw thread, we recommend using good Allen wrenches, applying a few drops of WD40, and heating each screw well with a heat gun before unscrewing it.

And now we can remove the rear wheel from our Dualtron Victor.

Removing the two half-rims

Remove the two half-rims.

And remove the punctured inner tube.

Removing the punctured inner tube + tip

If your tire is still good and you plan to reuse it, here’s a little trick to easily find the spot, “the zone,” where there may be a hidden nail that could puncture your new inner tube.

Before removing our old inner tube, we mark the location of the valve on the tire with a marker or a piece of tape.

Then we can remove the punctured inner tube and inflate it.

Afterwards, we can submerge it in water to find the spot where it was punctured.

And there we can precisely locate and inspect the area where there may be debris stuck.

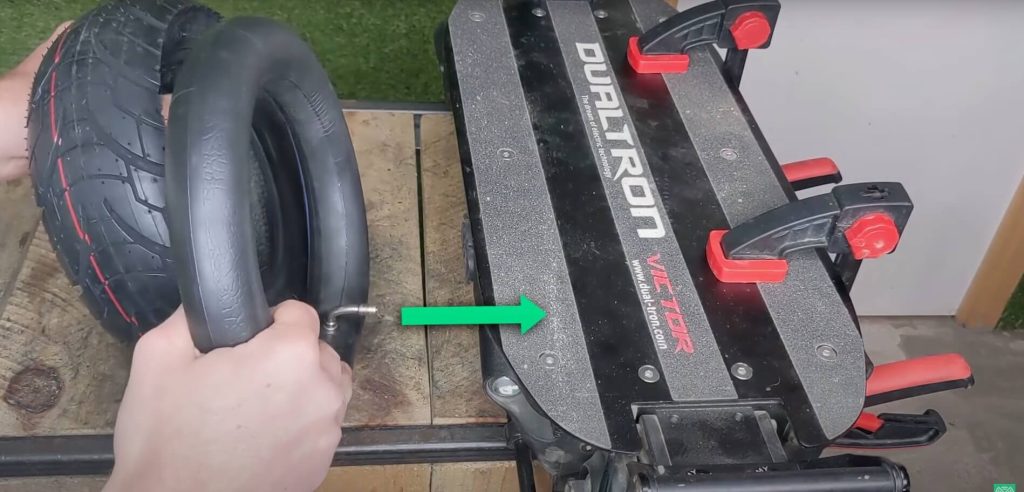

Mounting the new Road 80/65-6 tire

Now we can proceed with mounting the new tire.

We start by checking the direction of rotation using the arrow on the side of the tire.

And we place the inner tube inside, with the valve pointing to the right.

Placing the rims on the tire

Then we can put the two half-rims back on the tire.

To ensure they are aligned properly, we can pass an Allen key through the holes to position them correctly.

And we make sure that no part of the inner tube touches the rim.

To avoid pinching it when we close everything.

Next, it’s not mandatory at all, but to facilitate the reinstallation of the wheel, we like to hold the two rims together with two zip ties.

Installing the repaired rear wheel on the motor

Before reassembling the wheel, I take the opportunity to clean the motor and degrease the brake disc.

Then I apply a drop of WD40 to make the rim slide easily around the motor.

And I align the wheel with the holes.

Screwing the rear wheel onto the scooter

And now, we can gradually tighten the 6 screws.

Once everything is tightened, I secure the new tire with the strap.

Reinstalling the Dualtron rear fork

And I apply a few drops of WD40 to the two axles, so that the arm slides more easily.

Then we position the arm on the two axles. It requires some precision, and it’s important to take a good look at what we’re doing.

And when we have successfully aligned the gear wheels, we insert the arm into its housing using a mallet.

And now, we can:

Reattach our mudguard by tightening the two screws.

Put back the two washers.

Tighten the two nuts.

Tire Pressure for Dualtron Victor

And inflate the new tire of this little Dualtron Victor.

Other tutorials that may interest you

Dualtron Mini – FRONT WHEEL – How to change the tyre and inner tube

How to change the tire and inner tube on the front wheel of a Dualtron Mini / Minimotors electric scooter

Dualtron Mini – Changing the tyre and inner tube on the REAR WHEEL

In this tutorial, we show you how to disassemble your rear wheel, remove your old inflatable tyre and your punctured inner tube. Then install a new V3 – 8 ½ x 2 tyre with a new 8 1/2×2-156 Bent Valve 110/90 inner tube.

PURE AIR Changing the Tyre and Inner Tube – Rear Wheel

We’ll show you step by step how to change the tyre and inner tube on the rear wheel of your Pure Air electric scooter. This repair is easy, and you’ll be able to do it without any trouble!